Collection: Carbotech Performance Brakes

Choosing the Correct Compound

-

AX6 - The AX6™ is specifically engineered for Autocross applications. A high torque brake compound delivering reliable and consistent performance over a very wide operating temperature range of 50°F to 1000°F + (10°C to 537°C+). The advanced compound matrix provides an excellent initial bite, high coefficient of friction at lower temperatures along with very progressive brake modulation and release characteristics. NOT FOR STREET USE!

- XP8 - A high torque brake compound with a wide operating temperature range of 200°F-1250°F+ (93°C to 676°C+). Carbotech™ XP8™ is the first of our racing compounds. It provides good initial bite at race temperatures, high coefficient of friction, excellent modulation and release characteristics. XP8™ offers extremely high fade resistance and is very rotor friendly. It’s perfect for track day use with any tire. NOT FOR STREET USE!

- XP10 - When Carbotech™ unleashed the XP10™ to the general public it immediately gathered multiple regional, divisional, and national championships. The XP10™ has a very strong initial bite with a coefficient of friction and rotor friendliness unmatched in the industry. Fade resistance is in excess of 1475°F (801°C). XP10™ still maintains the highly praised release, excellent modulation and rotor friendliness that have made all Carbotech™ compounds so successful. NOT FOR STREET USE!

- XP12 - Another highly successful XP™ series compound with an excellent initial bite, torque and fade resistance over and above the XP10™ compound. XP12™ has temperature range of 250°F to 1850°F+ (121°C to 1010°C+). The XP12™ has that excellent Carbotech™ release and modulation that has made all other Carbotech™ compounds so successful. The XP12™ is more rotor aggressive than XP10™, but compared to the competition the XP12™ is still very rotor friendly. NOT FOR STREET USE!

- 913 - A D.O.T.-approved high-performance compound for brake shoes on high performance street vehicles and race cars. Carbotech™ Kelated Metallic (CKM) achieves a very high coefficient of friction (approx. 0.48 to 0.50) by taking advantage of a chemical reaction within the friction mass, which creates a tri-alloy metallic film at the liner/drum interface when subjected to heat and pressure. Designed to overcome the shortcomings of other liner materials, CKM is very versatile and provides excellent braking performance in a wide variety of applications. This compound demonstrates excellent wear characteristics and a very high resistance to lock-up under hard braking. Optimal recommended operating temperature range is from ambient to 750°F.

-

Carbotech AX6 Brake Pad | Legend Wilwood Caliper

Regular price From $158.00 USDRegular priceUnit price / per -

Carbotech XP10 Brake Pad (Pre-Bed Option) | Legend Wilwood Caliper

Regular price From $171.00 USDRegular priceUnit price / per -

Carbotech XP12 Brake Pad (Pre-Bed Option) | Legend Wilwood Caliper

Regular price From $178.00 USDRegular priceUnit price / per -

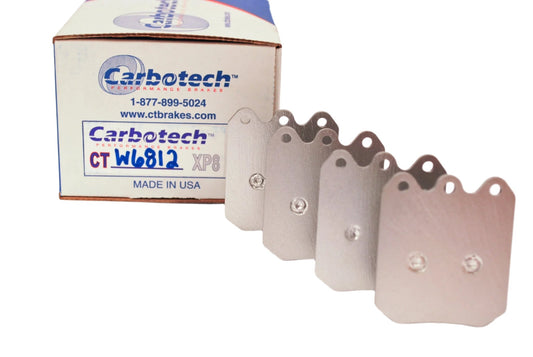

Carbotech XP8 Brake Pad (Pre-Bed Option) | Legend Wilwood Caliper

Regular price From $164.00 USDRegular priceUnit price / per